All Categories

Featured

Table of Contents

- – Rv Rubber Roof Replacement Cost Villa Park, CA

- – OCRV Center

- – Rv Roof Maintenance Villa Park, CA

- – Rubber Roof For Camper Villa Park, CA

- – Rv Roof Replacement Villa Park, CA

- – Rv Rubber Roof Maintenance Villa Park, CA

- – Rv Rubber Roof Repair Villa Park, CA

- – Repair Rv Roof Leak Villa Park, CA

- – Motorhome Roof Replacement Villa Park, CA

- – Rv Roof Repair Fiberglass Villa Park, CA

- – Rv Trailer Roof Repair Villa Park, CA

- – Rv Roof Replacement Villa Park, CA

- – Rubber Roof For Rv Villa Park, CA

- – Rv Rubber Roof Replacement Cost Villa Park, CA

- – OCRV Center

Rv Rubber Roof Replacement Cost Villa Park, CA

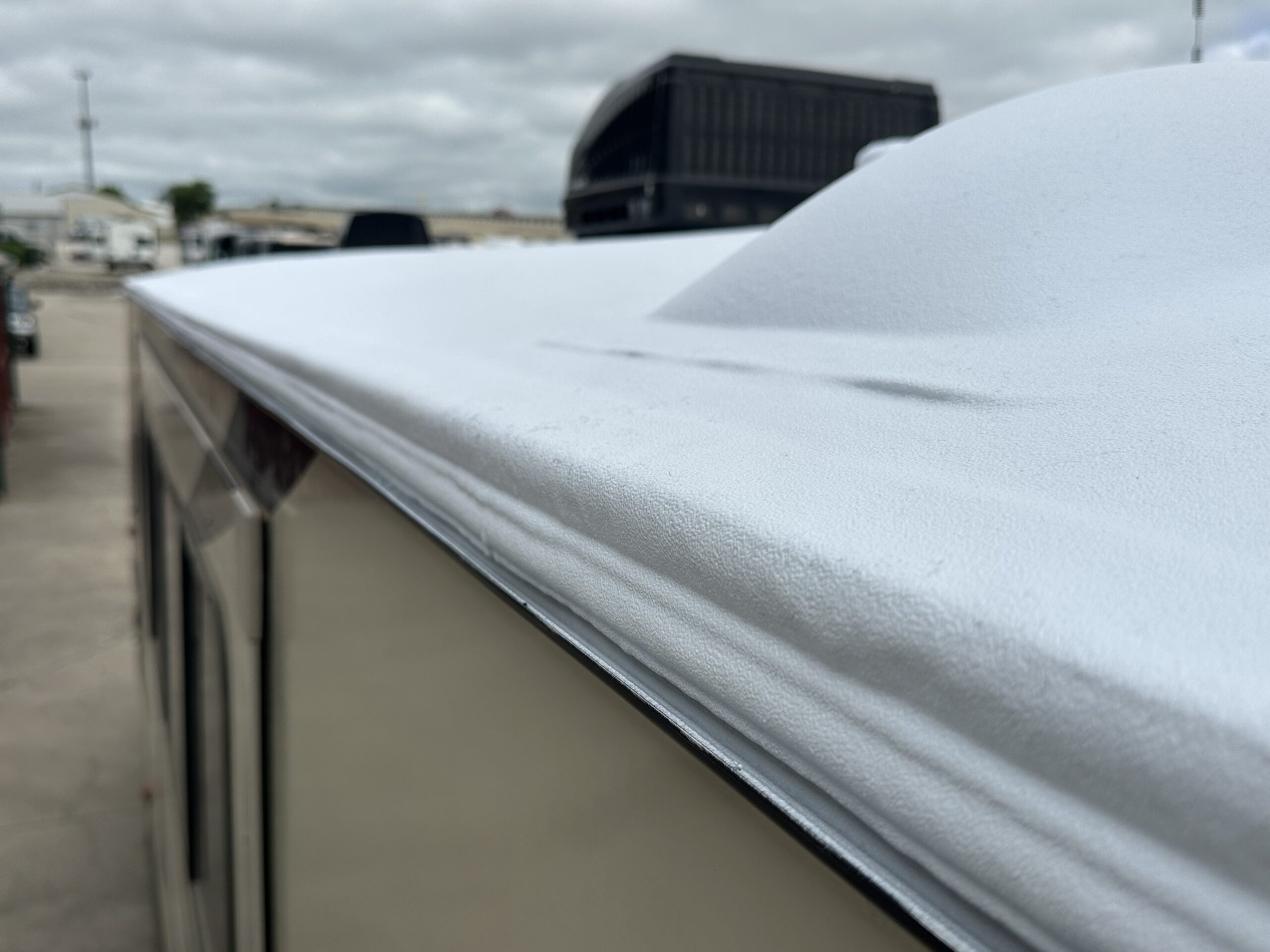

He strolls you detailed with the basic process for patching and enhancing TPO motor home roofing system lining with rubber tape strips, which you can get from nearly any respectable dealership. Dicor makes a fantastic set that Dave constantly suggests. In this instance, the recreational vehicle's TV antenna has worn small openings right into the TPO motor home roofing system, so to avoid gurgling under the membrane from rainfall and sunlight damages, Dave utilizes these rubber spots to cover the openings and maintain the roofline watertight.

This is especially true when patching larger openings. So that's it, 10 minutes of your time and a fail-safe set. Benefit from Dave's expert ideas to stop that small cut on your TPO RV roofing from becoming an expensive migraine! When we mindful top right here, we cleaned this roof and we found a number of places, we see right below where this roof antenna comes down in.

Rv Roof Maintenance Villa Park, CA

It's just a rubber, the old design is just like this, and it gets chalked white, it'll start to wear away, yet I obtain any type of sort of moisture under below and it's gon na begin to function in. Now, these 2 spots happen to find from the antenna, as this comes down below and it's wearing right into 'em.

And I'm gon na put this in there just to provide it a little bit if reinforcement to see to it that I do not pierce that in future so. Obtained one right below, one right here, so I'm simply gon na take and cut this about two lengths, right there. And this simply takes place to be a, a leakages, Dicor makes it, DiSeal they call it, same sort of material, and it simply has a flap on below.

Membrane can be glued either side down. Membrane layer has to be installed onto clean wood surface area, do not set up on top of existing membrane, adhesive, etc. Get rid of all debris off roofing system with air tube.

That is, fold it in fifty percent so half of the roofing is exposed. Apply sticky in a damp film thickness of 8-10 mils with a short-napped paint roller to the exposed fifty percent of the roofing system decking, brush can be used but is a lot more challenging.

Rubber Roof For Camper Villa Park, CA

Alternative technique, essential membrane layer in location utilizing" staples 3"-5" apart after that apply bar. If roof-edge moldings are not set up on roof covering throughout this moment membrane will peel-up as drying. 8. Apply putty/butyl tape to the behind of the front and back termination moldings/caps. Front cap will certainly lay on top of the membrane, membrane needs to lay on top of the rear cap.

Both sides of the front and rear roofing molding need to be sealed with caulk/sealant. Using an energy knife "x" reduced all roofing openings.

There is no need to spread the sealant as you are using it. * Butyl tape gives the "Primary Seal" versus water infiltration or infiltration in these membrane layer roof settings up.

Rv Roof Replacement Villa Park, CA

To attain finest bond, put on both substratums with 5-6 mil coat weight and allow to dry, after that laminate to membrane and apply pressure with roller to guarantee 100% contact. Diluent Water, if needed. Use as gotten. Clean-up needs only warm water. Shop item in an amazing, dry area. Product ought to not be saved in straight sunlight.

Eye get in touch with If product get in touches with eye, flush with water for at least 15 mins and look for medical interest immediately. Skin call If product get in touches with skin, laundry impacted location with soap and water. Look for medical attention if inflammation establishes or lingers. Wash infected apparel before reuse. Inhalation Move based on fresh air in case of unexpected breathing of vapors or decay products.

Lots sealer cartridge in caulking gun. Place nozzle right into joint and apply sealant right into space. Clean hands and devices extensively prior to cleaning with soap and water.

PRECAUTIONNot for inner intake. Direct get in touch with of uncured sealer irritates eyes and may irritate skin. In instance of eye get in touch with flush eyes with water for 15 mins and call a medical professional. In case of skin call, completely clean skin with soap and water. In instance of ingestion look for medical attention right away.

Rv Rubber Roof Maintenance Villa Park, CA

Some RV repairs can be briefly put on hold, however a RV roof repair work is NOT one of them. Stopping working to fix damages to your motor home's roof covering can trigger a discouraging and costly collection of scenarios that will just worsen with time. Because roof covering fixing is such a vital piece of recreational vehicle maintenance, we're sharing some crucial ideas for searching for and fixing motor home roofing holes.

The ever-changing environment can trigger caulking and seals to expand and contract continuously, which can ultimately cause openings, cracks, or gaps in the roofing. Openings can also happen when you're on the step. A tree branch might scuff and puncture the rooftop if you were to underestimate the elevation of a tree arm or leg.

If your RV happens to be parked there at the time, your RV roofing could sustain substantial damage. Not all Recreational vehicles have the very same type of roof, of course.

TPO roofing systems are readily available in a range of densities, depending on the supplier's specifications. Whether or not the thicker product is more reliable over the long run seems to be a warm topic in RV discussion forums. TPO roofs have a laminate cover that assists keep them from damaging and establishing cracks.

Rv Rubber Roof Repair Villa Park, CA

It can likewise be sealed with solvent welding and connected with adhesives. For an also a lot more thorough take a look at the various types of products made use of for RV roofings, look into PVC vs TPO vs EPDM Motor Home Roofing System Options: Which Is the very best Choice? Fiberglass is an additional typical motor home roofing material that's remarkably resilient.

And be specifically mindful if your roof is wet to make sure that you do not slide and drop off! A fast check of the sealant around vents, followers, photovoltaic panels, ac unit, and antennas every one month or so maintains our RV roofing in excellent problem, preventing potentially expensive leakages. This Dicor sealant has actually broken severely enough that it can easily be enabling water to permeate with the roofing system and requires to be cleaned up and re-sealed.

Try to find cracks and indicators of setting or separation. You'll additionally wish to examine locations around vents, a/c unit, antennas, solar panels, and any type of additional setups. Clearing your motor home's roofing of hazardous materials is just one of the most effective preventative procedures you can take. You'll intend to do a basic sweeping of your RV's roof to remove excess leaves and debris.

Repair Rv Roof Leak Villa Park, CA

Next, spray the roof with tidy water to get rid of loose dirt and grime. During the cleaning process, offer additional attention to locations where mold and mildew, mildew, tree sap, bird droppings, or other spots are existing. Wash extensively and frequently to stop residue and crud build-up.

Motorhome Roof Replacement Villa Park, CA

It comes in a number of different mixes of size & size, and several various colors: Clear your steel Recreational vehicle roofing of any particles before you start a repair work. Examine the repair service location very carefully and take note of what's around it. The secret is to make certain any kind of seams are totally covered by the tape, overlapping if needed.

Rv Roof Repair Fiberglass Villa Park, CA

Substantial damage most likely calls for specialist support, which can be expensive. You're also at their grace in regards to the repair work timeline. If you come in handy, it's possible to deal with small fractures and imperfections in a fiberglass roof. Just recognize your restrictions and when to hire an expert to avoid future troubles.

Sand the broken area to give a smooth surface area for repair service sealants. If you're certain, you can also use fiberglass resin, and fiberglass cloth if required, to make the repair service yourself.

Rv Trailer Roof Repair Villa Park, CA

Keep in mind that the warranty on your roof might depend on having your recreational vehicle inspected every year and proof that you've been doing preventative maintenance. Maintaining your motor home roof seals is important to stop a leakage and severe damages. The seam where the rubber roof covering satisfied the sidewalls enabled water to seep below, doing comprehensive (and expensive) damage to the foundation.

One of the most important skills you can grasp for preserving your motor home is roof repair service. It's simple to overlook damage to a motor home roofing, yet it's one of the most important facets of camper upkeep. Most individuals that have been RVing for any kind of length of time have actually come to be familiar with the fact that they will have to do some repair and maintenance on their very own at some time.

When it concerns holding off motor home repair and maintenance, among the worst points that can happen is water damage. When there's a concern with your roofing, it takes place rapidly (Rv Roof Repair Service Near Me Villa Park). Water damages can be prevented or lessened by fixing the leakage yourself. Apart from that, there's a feeling of accomplishment in doing points oneself.

Rv Roof Replacement Villa Park, CA

These can deteriorate the roofing material gradually, weakening it. There are cleansers created particularly for motor home roofs and each kind of product. If you're functioning on a vast location, tape off the rest of your RV and cover it with plastic to stop roof covering cleansers or sealers from dripping down the sides.

Another point that all RV roof coverings share is the kind of repair services that they can require. The sealant, joints, and spot openings and slits are the three things you could mend. If your EPDM or TPO rubber roof appears to be half-cracked or chalky, a fresh layer of sealant is what it requires.

When purchasing the rubber roofing finishes or sealers, maintain your motor home's measurements in mind to guarantee you receive the proper amount. After washing the whole roofing system and enabling it to dry, use a layer of paint to the roofing system making use of a roller. Rv Roof Repair Service Near Me Villa Park. Make certain to review and comply with the guidelines on the sealant bundle for ideal preparation

A spot will certainly be required if you discover a small leak or tear on your recreational vehicle roofing. The good news is, makers have actually created repair work and recreational vehicle roofing adhesives that are simple to use and long-lasting. The majority of patches require little prep work besides cleaning the damaged area and using the patch over it, similar to a band-aid.

Rubber Roof For Rv Villa Park, CA

Fiberglass roofs' top layer, like RV rubber roof coverings', can oxidize with time, providing a flaky, chalky appearance. Remove any type of loosened, crinkled portions of the finish prior to cleansing and sand the roof's surface using penalty to medium grit sandpaper afterwards. The finishing will certainly stick better to a slightly abraded surface.

After the area has been smoothed and cleansed, add fiberglass patches and glue layer by layer, as routed by the fixing kit. At the end, coat your RV with a sealant to the task and refinish the area as needed. The resealing of light weight aluminum and various other metal recreational vehicle roof coverings is finished with a specific coating produced an aluminum roofing product.

The simplest method to fix a steel roofing with more severe damages is to change the steel panel, which is a procedure that may differ based upon your recreational vehicle. You could be able to repair your steel roofing system making use of a peel-and-stick patch depending upon the degree of the damages. Make certain you select one that is specifically planned for steel roofings, as the adhesive chemistry differs.

Rv Rubber Roof Replacement Cost Villa Park, CA

A pal needs to move into it quite fast. I'm thinking of using 'blue board' foam insulation, in between the 'rafters' to hold up the roofing product (which is currently sagging down) and make the roof drainpipe. I will also need to spot a pair tiny holes where a tree branch arrived at the roofing (water dripping in these openings is what rotted the plywood) and a couple of other tiny spots where the rubber is doing poor.

I'm searching for different techniques. Any type of experiences and pointers on fixing a camper roofing? Thx-Ace.

They took till last week to do it. The customer was very dismayed due to the fact that they had Spring Damage outdoor camping strategies, and we didn't understand if we 'd be able to get the repair work done in time due to all the hold-ups.

OCRV Center

Address: 23281 La Palma Ave Yorba Linda, CA 92887Phone: (714) 909-1444

Email: [email protected]

OCRV Center

But he called Progressive and should have been not-so-nice since he obtained the adjustor's manager included. When the one in charge man spoke to the client, he was playing it up large. He stated in order to obtain the repairs done as soon as possible so they could make their trip, we can buy parts overnighted and they would certainly cover it.

Rubber Roof For Rv Villa Park, CARv Roof Maintenance Villa Park, CA

Rv Roof Replacement Villa Park, CA

Rv Roof Maintenance Villa Park, CA

Rubber Roofing For Campers Villa Park, CA

Repair Rv Roof Leak Villa Park, CA

Rubber Roofing For Rv Villa Park, CA

Rubber Roofing For Rv Villa Park, CA

Rv Rubber Roof Repair Villa Park, CA

Repair Rv Roof Villa Park, CA

Rv Roof Repair Near Me Villa Park, CA

Rv Roof Repair Villa Park, CA

Rv Fiberglass Roof Repair Villa Park, CA

Rv Roof Maintenance Villa Park, CA

Rv Rubber Roof Replacement Villa Park, CA

Rv Rubber Roof Replacement Villa Park, CA

Rv Roof Leak Repair Villa Park, CA

Roof Repair For Rv Villa Park, CA

Rv Rubber Roof Maintenance Villa Park, CA

Repair Rv Roof Leak Villa Park, CA

Rv Roof Leak Repair Near Me Villa Park, CA

Epdm Rv Roof Repair Villa Park, CA

Epdm Rv Roof Repair Villa Park, CA

Motorhome Roof Replacement Villa Park, CA

Repair Rv Roof Villa Park, CA

Rubber Roof For Rv Villa Park, CA

Roof Repair For Rv Villa Park, CA

Rv Roof Maintenance Villa Park, CA

Rubber Roof For Camper Villa Park, CA

Rv Roof Leak Repair Villa Park, CA

Repair Rv Roof Villa Park, CA

Roof Repair For Rv Villa Park, CA

Rubber Roof Installation Villa Park, CA

Rv Roof Replacement Villa Park, CA

Best Rv Roof Repair Villa Park, CA

Rv Rubber Roof Maintenance Villa Park, CA

Rv Rubber Roof Replacement Villa Park, CA

Rv Trailer Roof Repair Villa Park, CA

Rv Slide Out Roof Repair Villa Park, CA

Rv Rubber Roof Replacement Villa Park, CA

Roof Repair For Rv Villa Park, CA

Rv Roof Maintenance Villa Park, CA

Rv Rubber Roof Maintenance Villa Park, CA

Rv Roof Repair Fiberglass Villa Park, CA

Rubber Roof Installation Villa Park, CA

Rv Roof Repair Service Near Me Villa Park, CA

Rv Roof Maintenance Villa Park, CA

Rubber Roofing For Campers Villa Park, CA

Resealing Rv Roof Villa Park, CA

Rv Rubber Roof Replacement Cost Villa Park, CA

Rv Roof Repair Service Near Me Villa Park, CA

Rv Roof Leak Repair Near Me Villa Park, CA

Rv Rubber Roof Replacement Cost Villa Park, CA

Rv Trailer Rubber Roof Repair Villa Park, CA

Best Rv Roof Repair Villa Park, CA

Rubber Roof For Rv Villa Park, CA

Resealing Rv Roof Villa Park, CA

Rv Roof Repair Near Me Villa Park, CA

Rv Rubber Roof Maintenance Villa Park, CA

Replace Rv Roof Villa Park, CA

Rv Roof Leak Repair Villa Park, CA

Best Rv Roof Repair Villa Park, CA

Rv Roof Repair Service Near Me Villa Park, CA

Replace Rv Roof Villa Park, CA

Epdm Rv Roof Repair Villa Park, CA

Rv Rubber Roof Replacement Villa Park, CA

Rv Rubber Roof Replacement Cost Villa Park, CA

Roof Repair For Rv Villa Park, CA

Rubber Roof For Camper Villa Park, CA

Rubber Roofing For Campers Villa Park, CA

Rubber Roof For Rv Villa Park, CA

Class C Rv Roof Repair Villa Park, CA

Rubber Roofing For Rv Villa Park, CA

Rv Roof Repair Fiberglass Villa Park, CA

Rv Fiberglass Roof Repair Villa Park, CA

Rv Roof Replacement Villa Park, CA

Rubber Roofing For Rv Villa Park, CA

Repair Rv Roof Leak Villa Park, CA

Best Seo Services Pricing Villa Park, CA

Near Seo Optimization Services Villa Park, CA

OCRV Center

Table of Contents

- – Rv Rubber Roof Replacement Cost Villa Park, CA

- – OCRV Center

- – Rv Roof Maintenance Villa Park, CA

- – Rubber Roof For Camper Villa Park, CA

- – Rv Roof Replacement Villa Park, CA

- – Rv Rubber Roof Maintenance Villa Park, CA

- – Rv Rubber Roof Repair Villa Park, CA

- – Repair Rv Roof Leak Villa Park, CA

- – Motorhome Roof Replacement Villa Park, CA

- – Rv Roof Repair Fiberglass Villa Park, CA

- – Rv Trailer Roof Repair Villa Park, CA

- – Rv Roof Replacement Villa Park, CA

- – Rubber Roof For Rv Villa Park, CA

- – Rv Rubber Roof Replacement Cost Villa Park, CA

- – OCRV Center

Latest Posts

Plumbing Repairs Near Me Carmel Mountain Ranch

Plumbing Repair Near Me Del Mar

Slab Leak Repair Carlsbad

More

Latest Posts

Plumbing Repairs Near Me Carmel Mountain Ranch

Plumbing Repair Near Me Del Mar

Slab Leak Repair Carlsbad