All Categories

Featured

Table of Contents

- – Rv Trailer Repair Shops Near Me Silverado, CA

- – OCRV Center

- – Trailer Awning Replacement Silverado, CA

- – Trailer Restoration Silverado, CA

- – Travel Trailer Roof Replacement Silverado, CA

- – Trailer Awning Replacement Silverado, CA

- – Trailer Floor Repair Silverado, CA

- – Travel Trailer Repairs Silverado, CA

- – Rv Trailer Repair Shops Near Me Silverado, CA

- – Horse Trailer Repair Near Me Silverado, CA

- – Trailer Windows Replacement Silverado, CA

- – Travel Trailer Furniture Silverado, CA

- – Fifth Wheel Repair Near Me Silverado, CA

- – Fifth Wheel Service Silverado, CA

- – Travel Trailer Replacement Windows Silverado...

- – Rv Trailer Repair Near Me Silverado, CA

- – OCRV Center

Rv Trailer Repair Shops Near Me Silverado, CA

And then, brr, brr, must be able to just drive some screws. The batten is simply acting like an actually large washer to make sure that that fabric does not have the chance to tear via and come loose.

So the following thing inside below is to seek a factor where we reach excellent material, and after that connect into that with a brand-new item in such a way that structurally is gon na job. And likewise just is easy sufficient to do. Let me get some devices drawn with each other, and then we'll look at out with the old and in with the new right here.

Trailer Awning Replacement Silverado, CA

I've obtained a bad end, conveniently identified, since that wood was in really, really bad form. I'm looking for a part below where it gets sound.

If I had to come back even more with the system I will make use of below, I would be okay with that said. If in order to remove negative product, I had to reduce back here where I'm not over a steel frame element, I would certainly do that. What I've done so far lies the steel.

Trailer Restoration Silverado, CA

And the following thing, allow's obtain that poor place reduced out. That went well. And I have actually currently got a brand-new piece cut.

There we go. The secret to this are items of scrap plywood. And combined with the plywood, we're going to add glue and screws, and that is really gon na make this basically simply like having one lengthy piece once again when we're done.

I have obtained in my warm little hands, an additional item to go on that side. I just have to obtain my platform out of the method here.

Travel Trailer Roof Replacement Silverado, CA

Since of making use of that, that's part of the reason that I desired to make certain those battens got under the material. And the factor being that that mineral woollen, it's got some density to it.

So when I'm cutting this item, the item that's gon na complete right here, I would love to maintain the factory edge on that particular end butting versus the factory edge that's currently in position, and after that the cut edge goes out right here up versus the wall surface. Currently, if you need to do a trim, you have to do a trim, and in this situation I did.

Trailer Awning Replacement Silverado, CA

So if you got ta do it, you obtained ta do it, yet it in the ideal globe, manufacturing facility edge to factory edge right here on the lengthy seams, and on the short seams where items are fulfilling. The various other point is that we intend to be fifty percent on a joist. What I indicate by that is that this chunk of plywood is fifty percent on this joist, and after that the next item of plywood is gon na come on below, so it's got something to be attached to, and that's simply a, you recognize, a building and construction standard that you constantly follow when you're doing floor covering or roofing.

There aren't any type of pieces of insulation laying on top of the framework. I have actually got, if you keep an eye out here, I have actually got these places marked on the wall, to make sure that as I occur with a screw gun, extra on that particular in a second, I know that sleeper, that joist exists, center exists, facility is there.

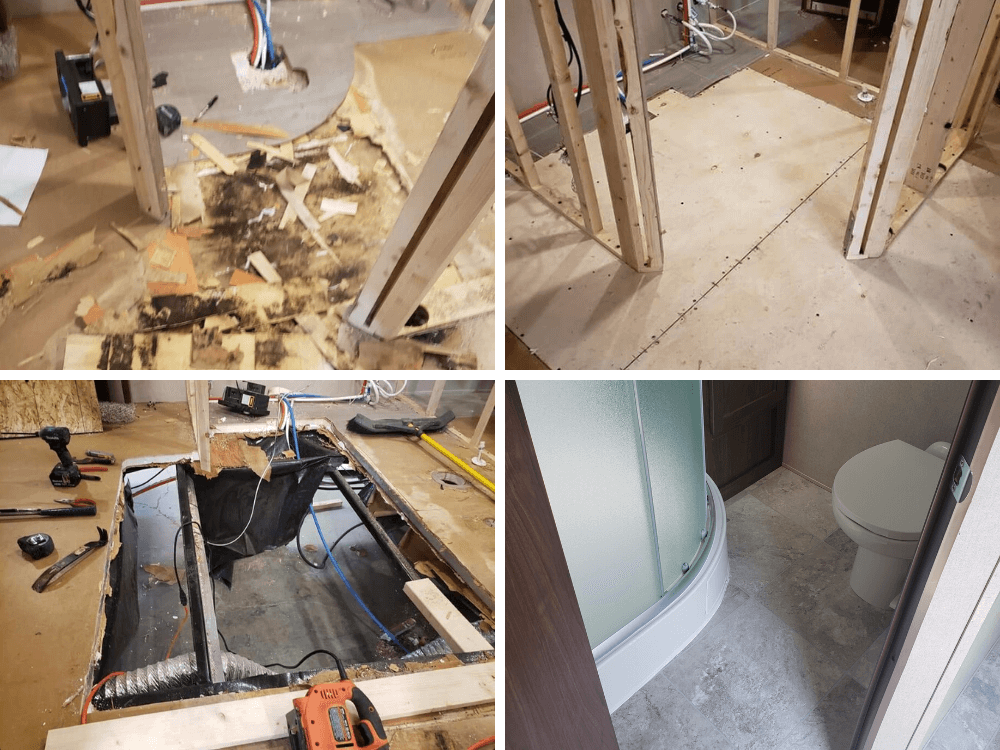

Trailer Floor Repair Silverado, CA

I don't have a stapler that'll do that, yet I do have a screw weapon that I can use to drive long screws. All right, a great deal of chatting, and let's look at obtaining the plywood to come in.

Well, we ended with a great deal of screwing around.The entire flooring was a great deal of screwing about. Simply a whole lot of little fussy things to do to get this right, yet absolutely worth doing, because certainly there were some poor areas in here that had to go. Silverado Travel Trailer Floor Repair. With those screws, if there's any location where you seem like you might've missed, get a common cordless screwdriver, back those screws out

Travel Trailer Repairs Silverado, CA

That deals with this floor covering project, and it was interesting, yet I will claim, I am glad it's done.

In the majority of cases, a rotten recreational vehicle floor shows a water leakage somewhere in the roofing or wall surfaces, it might likewise be caused by a leak in the RV's plumbing. Inspect the rotten location carefully. Inspect neighboring wall surfaces, windows, the roofing system above, and any type of water lines or drain pipes in the area.

Once you have actually found all of the soft places, cut and peel off back the laminate or carpeting to disclose the rotten subfloor. Some individuals select to do this step extremely carefully, cutting along the wall surface, so they have the ability to utilize the exact same floor covering after the repair services are made. Regardless of just how you deal with it, maintain peeling off the floor covering back in all instructions from the soft area till you find great, solid timber that is not blemished on all 4 sides.

Rv Trailer Repair Shops Near Me Silverado, CA

This can be done utilizing a small saw to cut up the subfloor and a crowbar to dig the wood out. If there is foam under your subfloor, take care to remove the timber, however not the foam. If there are wooden supports under your subfloor, you will wish to remove enough timber that you meet assistances on a minimum of two sides and after that reduced the opening to be a straight-sided rectangle to make points later when adding new wood.

You do not desire any kind of broken timber continuing to be, as this can really cause the brand-new timber to begin to rot all over again. Once the harmed subfloor is gone, allow any type of revealed timber framework and the wood around the soft place dry out entirely. This can take a week or more, yet it will help to ensure you won't run into the precise very same trouble once you complete the recreational vehicle flooring replacement.

Horse Trailer Repair Near Me Silverado, CA

This can be accomplished with a sprayer utilized to use the antifreeze to the surface of the timber, making certain to let the timber dry for a week or even more after.

It is likewise feasible to inject the epoxy right into the wood for also more strengthening power. Depending on the hardener and epoxy that you buy, you will have anywhere from a couple of mins to an hour to work with it before it starts to solidify. Nonetheless, you will certainly require to wait a week or 2 before the stuff sets totally.

You will certainly require to cover the recently laid subfloor. You could reuse the RV flooring you brought up, however RV floor replacement can be a fantastic opportunity to upgrade to a different product. Not certain which type of flooring is ideal? Well, in locations that are prone to spills and moisture, like the bathroom and kitchen area, you'll most likely desire a vinyl or laminate recreational vehicle floor covering.

Trailer Windows Replacement Silverado, CA

Due to the fact that of using that, that's part of the reason that I wanted to make certain those battens got under the textile. And the factor being that that mineral wool, it's got some thickness to it.

So when I'm reducing this piece, the item that's gon na fill out here, I want to keep the manufacturing facility side on that particular end butting against the manufacturing facility edge that's already in position, and after that the cut edge heads out here up versus the wall surface. Now, if you need to do a trim, you have to do a trim, and in this situation I did.

Travel Trailer Furniture Silverado, CA

If you obtained ta do it, you obtained ta do it, however it in the excellent globe, factory side to manufacturing facility side below on the lengthy joints, and on the short seams where pieces are satisfying. The other thing is that we want to be fifty percent on a joist. What I mean by that is that this piece of plywood is half on this joist, and then the next item of plywood is gon na come on here, so it's obtained something to be secured to, and that's just a, you understand, a building and construction guideline that you constantly comply with when you're doing flooring or roof covering.

There aren't any portions of insulation laying on top of the framework. I have actually got, if you look out right here, I have actually got these places marked on the wall surface, to make sure that as I go along with a screw gun, much more on that in a 2nd, I understand that sleeper, that joist is there, center is there, center is there.

Fifth Wheel Repair Near Me Silverado, CA

I need to have an inch and a quarter staple entering into it. I do not have a stapler that'll do that, yet I do possess a screw weapon that I can utilize to drive long screws. So I'm doing this with a screw gun instead of a stapler. All right, a great deal of chatting, and let's check out obtaining the plywood ahead in.

Well, we finished with a great deal of screwing around.The entire flooring was a great deal of screwing about. Simply a great deal of little fussy things to do to obtain this right, however certainly worth doing, due to the fact that clearly there were some negative areas in below that had to go. With those screws, if there's any type of area where you feel like you may've missed out on, obtain a basic cordless screwdriver, back those screws out.

That deals with this flooring project, and it was interesting, but I will claim, I rejoice it's done.

Examine the rotten location carefully. Check neighboring walls, windows, the roofing system above, and any kind of water lines or drain pipes in the area.

Fifth Wheel Service Silverado, CA

As soon as you have actually located all of the soft areas, cut and peel back the laminate or carpet to expose the rotten subfloor. Some people choose to do this action extremely carefully, cutting along the wall, so they have the ability to use the same flooring covering after the repair work are made. Despite just how you deal with it, maintain peeling the flooring back in all instructions from the soft spot up until you situate excellent, solid wood that is not stained on all 4 sides.

This can be done making use of a small saw to reduce up the subfloor and a crowbar to dig the timber out. If there is foam under your subfloor, take care to remove the wood, but not the foam. If there are wood assistances under your subfloor, you will certainly intend to remove enough wood that you fulfill up with assistances on at the very least 2 sides and after that reduced the hole to be a straight-sided rectangle to make things later when adding new wood.

Travel Trailer Replacement Windows Silverado, CA

You do not desire any type of damaged wood continuing to be, as this can actually create the new wood to start to rot all over once again. As soon as the damaged subfloor is gone, allow any revealed timber framing and the wood around the soft place dry totally. This can take a week or more, yet it will certainly help to guarantee you will not run into the specific same problem as soon as you finish the RV flooring replacement.

Some picked to make use of antifreeze to kill any mold and mildew that may still be about. This can be achieved with a sprayer used to apply the antifreeze to the surface of the timber, making certain to allow the timber completely dry for a week or even more after. One more choice that can be made use of to kill the mold and mildew is a borax remedy.

Rv Trailer Repair Near Me Silverado, CA

It is likewise possible to infuse the epoxy right into the timber for a lot more strengthening power. Depending on the hardener and epoxy that you get, you will have anywhere from a few minutes to an hour to work with it before it begins to set. However, you will require to wait a week or 2 before the stuff solidifies entirely.

Last but not least, you will certainly require to cover the newly laid subfloor. You might reuse the recreational vehicle floor covering you brought up, but motor home floor replacement can be a great possibility to update to a various material. Not sure which kind of flooring is best? Well, in locations that are prone to spills and dampness, like the bathroom and cooking area, you'll most likely desire a plastic or laminate recreational vehicle flooring.

Trailer Windows Replacement Silverado, CAHorse Trailer Repair Near Me Silverado, CA

Fifth Wheel Repair Near Me Silverado, CA

Trailer Windows Replacement Silverado, CA

Fifth Wheel Repair Near Me Silverado, CA

Cargo Trailer Repair Silverado, CA

Travel Trailer Roof Replacement Silverado, CA

Travel Trailer Window Replacement Silverado, CA

Travel Trailer Floor Repair Silverado, CA

Cargo Trailer Repair Silverado, CA

5th Wheel Repair Near Me Silverado, CA

Travel Trailer Awning Replacement Silverado, CA

Camper Floor Repair Near Me Silverado, CA

Trailer Window Replacement Silverado, CA

Camper Trailer Service Silverado, CA

Travel Trailer Awning Replacement Silverado, CA

Travel Trailer Replacement Windows Silverado, CA

Rv Trailer Repair Shop Silverado, CA

Camping Trailer Repair Near Me Silverado, CA

Rv Travel Trailer Repair Near Me Silverado, CA

Camper Floor Repair Near Me Silverado, CA

Camper Floor Repair Near Me Silverado, CA

Rv Trailer Repair Near Me Silverado, CA

Travel Trailer Replacement Windows Silverado, CA

Rv Trailer Repair Near Me Silverado, CA

Travel Trailer Floor Repair Silverado, CA

Rv Trailer Repair Near Me Silverado, CA

Rv Trailer Repair Near Me Silverado, CA

Travel Trailer Awning Replacement Silverado, CA

Travel Trailer Replacement Windows Silverado, CA

Trailer Window Replacement Silverado, CA

Camper Trailer Service Silverado, CA

Rv Trailer Repair Shop Silverado, CA

Camper Trailer Service Silverado, CA

Trailer Restoration Silverado, CA

Fifth Wheel Service Silverado, CA

Trailer Floor Repair Silverado, CA

Travel Trailer Awning Replacement Silverado, CA

Travel Trailer Window Replacement Silverado, CA

Travel Trailer Floor Repair Silverado, CA

Camper Floor Repair Near Me Silverado, CA

Travel Trailer Ceiling Repair Silverado, CA

Trailer Roof Repair Silverado, CA

Travel Trailer Roof Replacement Silverado, CA

5th Wheel Repair Near Me Silverado, CA

Horse Trailer Repairs Silverado, CA

Trailer Window Replacement Silverado, CA

Rv Travel Trailer Repair Near Me Silverado, CA

Trailer Floor Repair Silverado, CA

Rv Trailer Repair Shops Near Me Silverado, CA

5th Wheel Repair Near Me Silverado, CA

Camper Trailer Service Silverado, CA

Horse Trailer Repair Near Me Silverado, CA

Trailer Windows Replacement Silverado, CA

Rv Trailer Repair Shops Near Me Silverado, CA

Trailer Restoration Silverado, CA

Trailer Floor Repair Silverado, CA

Horse Trailer Repair Near Me Silverado, CA

Travel Trailer Repairs Silverado, CA

Travel Trailer Service Silverado, CA

Trailer Awning Replacement Silverado, CA

Rv Trailer Service Near Me Silverado, CA

Trailer Windows Replacement Silverado, CA

Travel Trailer Repairs Silverado, CA

Travel Trailer Floor Repair Silverado, CA

Trailer Window Replacement Silverado, CA

Trailer Awning Replacement Silverado, CA

Rv Trailer Repair Shop Silverado, CA

Rv Trailer Repair Shops Near Me Silverado, CA

Rv Travel Trailer Repair Near Me Silverado, CA

Travel Trailer Siding Repair Silverado, CA

Cargo Trailer Repair Silverado, CA

Rv Trailer Repair Near Me Silverado, CA

Travel Trailer Roof Replacement Silverado, CA

Cargo Trailer Repair Silverado, CA

Camper Floor Repair Near Me Silverado, CA

Trailer Windows Replacement Silverado, CA

Travel Trailer Awning Replacement Silverado, CA

Close By Seo Services For Business Silverado, CA

Near Here Seo Expert Silverado, CA

OCRV Center

Table of Contents

- – Rv Trailer Repair Shops Near Me Silverado, CA

- – OCRV Center

- – Trailer Awning Replacement Silverado, CA

- – Trailer Restoration Silverado, CA

- – Travel Trailer Roof Replacement Silverado, CA

- – Trailer Awning Replacement Silverado, CA

- – Trailer Floor Repair Silverado, CA

- – Travel Trailer Repairs Silverado, CA

- – Rv Trailer Repair Shops Near Me Silverado, CA

- – Horse Trailer Repair Near Me Silverado, CA

- – Trailer Windows Replacement Silverado, CA

- – Travel Trailer Furniture Silverado, CA

- – Fifth Wheel Repair Near Me Silverado, CA

- – Fifth Wheel Service Silverado, CA

- – Travel Trailer Replacement Windows Silverado...

- – Rv Trailer Repair Near Me Silverado, CA

- – OCRV Center

Latest Posts

Tankless Water Heater Installers Leucadia

North Clairemont Toilet Plumbing Near Me

Bernardo Village Water Line Repair

More

Latest Posts

Tankless Water Heater Installers Leucadia

North Clairemont Toilet Plumbing Near Me

Bernardo Village Water Line Repair